Hastings NRV Refurbishment

Hastings NRV Refurbishment

Client

MTS

Value

60k

Duration

6 Weeks

Project Scope

-

Design, Install, Test & Commission a lifting frame that would allow the valve to be removed in the low head-height chamber.

-

Plan, Manage and Implement the removal works. Working safely with confined space working techniques and taking into account the tidal conditions in the chamber

-

Remove the mechanical components back to the workshop, reverse engineer the main components in order to machine and fabricate new stainless steel elements of the NRV

-

Reinstall all new-components, re-commission the valve and provide all relevant handover documentation

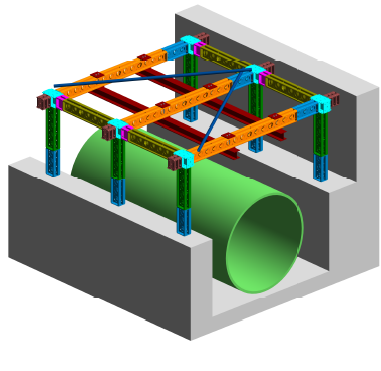

Lifting Frame Design & Install

Design of the frame was carried out to comply with all relevant standards. The frame was LOLER tested before use with a proof load applied. Due to the limited space available for test weights a bespoke frame was fabricated, installed and tested in order to apply the test load in-situ.

Flap Valve Removal

The counterweight was secured in a fabricated steel cradle. The large steel flap valve was then safely removed and restrained on chain blocks so the process of removing the mechanical components could begin. Working in tidal conditions within the chamber the components were carefully stripped, recorded and brought back to the workshop for engineering.

Engineering

All components were measured and logged and drawings and specifications developed for approval of the end user. Fabrication of all new stainless steel components / refurbishment of existing was carried out.

Repair and Reinstall

The NRV was successfully repaired and reinstalled in-situ working in the challenging conditions of the chamber.