Silvertown Flood Gate Refurbishment

Silvertown Flood Gate Refurbishment

Client

Tate & Lyle Sugars

Value

50k

Duration

8 Weeks

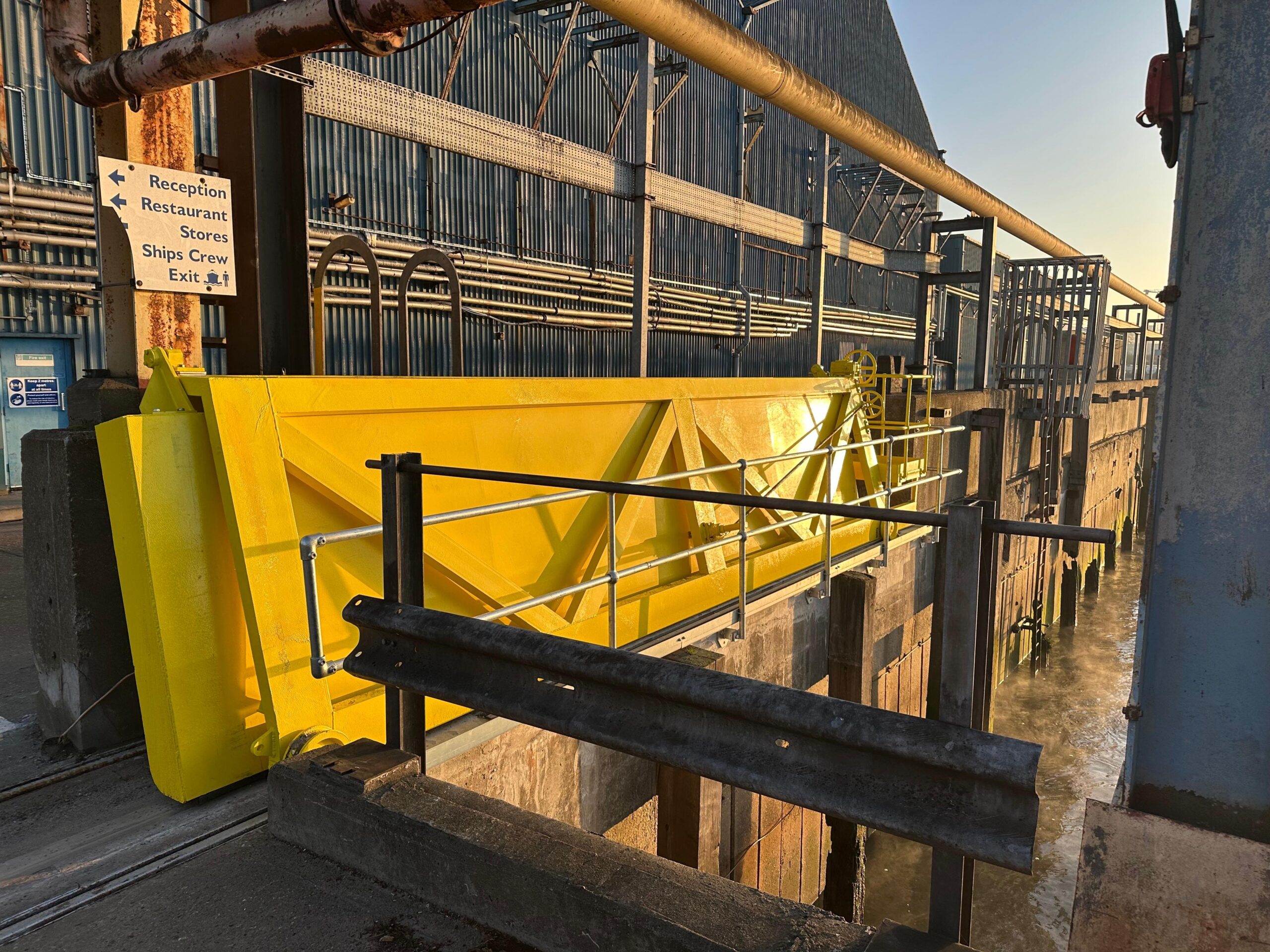

Tate & Lyles sugar refinery in Silvertown is the largest sugar refinery in Europe. Situated outside of the Thames Barrier the jetty entrances require flood protection gates which protect a vast area of East London from flooding. Working in this live operational environment, our scope was to remove the barriers and fully overhaul and refurbish them back into use.

As well as mechanically overhauling the gates themselves, GLE also carried out refurbishment of the rails which had started to corrode in the tough marine environment. The rails required breaking out, removal, replacement and re-casting with new concrete, with repairs also carried out to the river wall.

After initial disassembly on-site, removal was carried out using a high capacity HIAB. This working method meant that the haul road did not need to be closed to mobilise a crane and factory operations could be minimally affected.

The barriers were transported to our Kent workshop facility. Once in the workshop the barriers were stripped completely and a defect report issued for client approval

Working in this sensitive location GLE had to remain conscious of our duties to protect the river. Working from a scaffold provided both safe access and prevented any risk of debris or detritus falling into the river.

The rails required breaking out, removal, replacement and re-casting with new concrete. GLE undertook concrete repairs, using a repair mortar suitable for the aggressive atmosphere environment.

Demolition of the existing rails was carried out using a Brokk 70 remote operated breaker. Using this small breaker meant that the works could take place outside the river wall, further eliminating interface with factory operations and reducing HAVS exposure for our site ops

The gates were cleaned, shotblasted and recoated in marine grade epoxy paint. All new mechanical parts were machined in house or procured from our supply chain before the gates were re-assembled, tested and offered to the client for acceptance.

The gates were re-installed successfully, utilising the same lifting methods, before being commissioned and handed back into use.

Completed works

Completed works